All magnet materials demonstrate reversible strength loss as they approach Maximum Operating Temperature.

* NOTE: Unshielded open circuit ceramic magnets should not be subjected to more than 400°F.

Tolerances

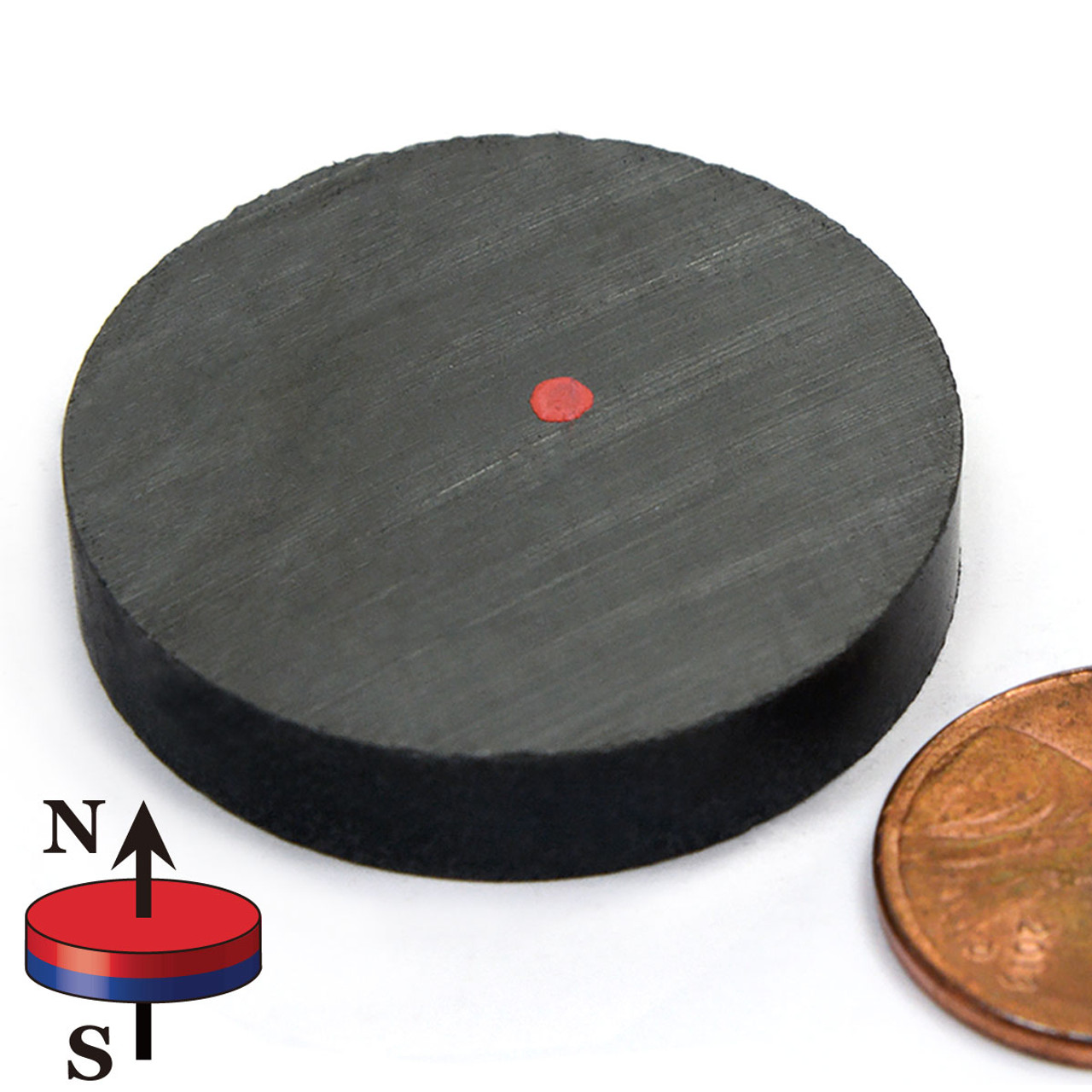

For as pressed material, tolerance on the thickness (direction of magnetization) is ± .005. Other dimensions are ± 2.5% or ± .010, whichever is greater. According to IMA standards, visual imperfections such as hairline cracks, porosity and minor chips are commonly found in sintered metallic magnets. A chipped edge is considered acceptable if no more than 10% of the surface is missing. Cracks are acceptable as long as they do not extend across more than 50% of pole surface.

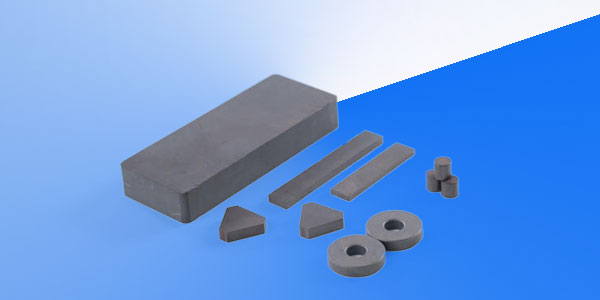

Ferrite magnets, also known as ceramic magnets, are a type of magnet that is made out of a mixture of metals that is called ferrite. Ferrite is made up mostly of a chemical element called iron oxide. Find the perfect alsace souvenirs stock photo. Huge collection, amazing choice, 100+ million high quality, affordable RF and RM images. No need to register, buy now! Ceramic magnets are made by mixing strontium carbonate and iron oxide and subjecting them to a chemical conversion at a very high temperature (982-1093/1800-2000 ºC/ºF). The resulting material, also known as hard ferrite, is then reduced to small particles by wet milling.

Magnetizing and Handling

Ceramic magnet material is extremely brittle and can chip or break if dropped on a hard surface, or if allowed to “jump at” an attracting object. Handle with care. The weakest grade of ceramic material is grade 1, which is typically non-oriented. Grades 5 and 8 are oriented ceramic material. Grade 8 is the strongest ceramic magnet material available (Refer to properties chart below). When making magnetic assemblies with ceramic, it is typically easier for production purposes to magnetize the product after assembly.

Ceramic Magnets Wholesale

Ceramic Magnets Walmart

Machining

Since ceramic material is so brittle, it requires special machining techniques and equipment. We are fully equipped to cut and grind ceramic material to your specifications.